Vol 8 No 4 2023 – 60

Naeem A. Mutlag1*, Adawiya S. M. Al-Rawi2 Mohammed D.Y. El-Jubouri3, Saddam H. Cheyed4

1University of Fallujah ; .Iraq

2College of Agricultural Engineering Sciences – University of Baghdad. Iraq

3Al-Karkh University of Science. Iraq

4College of Agricultural Engineering Sciences – University of Baghdad. Iraq:Saddam.hakeem@coagri.uobaghdad.edu.iq.

*Correspondence: naeem-admin@uofallujah.edu. Available from. http://dx.doi.org/10.21931/RB/2023.08.04.70

ABSTRACT

During the spring season of 2021, a field experiment was conducted at the College of Agricultural Engineering Sciences – University of Baghdad (Abi Ghraib location). To investigate the impact of nano iron concentrations and their application dates on the yield and its components of maize. A factorial experiment was carried out in a split-plot arrangement. The main plots occupied the spraying dates (beginning of the male flowering stage, 50% female flowering and completion of female flowering) and symbolized in sequence. At the same time, the iron concentrations (0, 100, 200 and 300 mg. L-1) occupied sub-plots according to RCBD with three replicates. The results revealed that the dates of spraying nano iron substantially influenced most of the features tested. The early date (beginning of the male flowering stage) gave the highest average length of the ear (16.374 cm), the number of rows per ear (16.3 row ear-1), and the number of grains per ear (563.4 grain ear-1) and the total grain yield of 6.096 tons ha.-1. The results also showed that the concentrations of nano iron 300 mg L-1were superior in all the characteristics of the yield components and the grain yield, as it produced the most significant average for ear length, number of rows, number of grains per row, number of grains in the ear, weight of 500 grains, and total grain yield. It is concluded from this study that spraying at the beginning of the flowering stage is the most responsive to spraying the nano iron element, especially at the concentration of 300 mg L-1.

Keywords: Nano iron; flowering stage; ear length; grain yield

INTRODUCTION

The maize crop is one of the vital grain crops that occupy the first place in terms of cultivated area and production and has a high nutritional value for humans and animals because its grain contains carbohydrates, proteins, oil, salts, minerals and vitamins, as well as being used as a raw material in many industries such as the manufacture of oils, starch and biofuels. Despite the importance of the crop, the gap between the amount of production and its needs in Iraq is still significant due to the low production rate. Among the most important reasons for the low productivity is the failure to use the genotypes appropriate to the cultivated environment and scientific methods for crop management and providing nutrients. The most important of these micronutrients is iron since maize is one of the crops sensitive to iron deficiency. Iron makes up 80% of chloroplast and helps metabolize RNA 1.

Foliar application is one of the methods used to provide nutrients to the plant by spraying. It is distinguished by its ease and speed, as well as its cost-effectiveness in terms of added fertilizers and labs, with the ability to add them simultaneously when symptoms of deficiency appear on the plant and reduce the risk of environmental pollution 2. It is also one of the most effective ways to deliver nutrients to the plant when the roots cannot supply them3. Iron is an activator of oxidation and reduction enzymes in the chain of electron transfer in the processes of active respiration and absorption, and of many other enzymes such as catalase and peroxidase, in addition to its role in the absorption of adequate nitrogen, which leads to an increase in leaf area and the production of proteins that help in building chlorophyll 4. The technology of nano-fertilizer, compared to the mineral fertilization process, is essential in increasing the activity of photosynthesis processes and making up for the lack of nutrients the plant needs. In addition to being environmentally friendly and less expensive, converting fertilizers added to nanoscale by changing their biological and chemical properties facilitates their absorption by the cell walls of plants. It supplies the soil with nutrients for a more extended period, as well as reducing environmental pollution problems 5.

Kobayashi et al. 6 noted that iron absorbed by plants from mineral soils is not sufficient for its needs despite its availability, as iron moves from the roots after absorption to the target parts and appears yellowing of young leaves as iron moves to the buds through the xylem and then to the old leaves by the process of transpiration and pressure root. It also takes part in most biological activities, such as respiration, production of chlorophyll, and photosynthesis. It is a cofactor for enzymes involved in electron or oxygen transport because iron is required for biological activities but is harmful in excess. Singh et al. 7mentioned that using nano iron sprayed on the plant at various growth phases substantially influenced increasing vegetative growth and the yield and its components. Golshahi et al. 8 showed that iron is one of the determinants of plant survival, and its presence is reduced in highly acidic areas because of its active participation in physiological and metabolic processes necessary for plant growth.

Al-Shaheen et al. 9 indicated the effect of iron nanoparticles on maize yield. It increased the transfer of processed materials from the source (leaves) to the sink (grain) by increasing the rate of chlorophyll in leaves and accelerating the photosynthesis process, growth and productivity, thus increasing the yield. The goal was to investigate the influence of nanoiron concentrations and the timing of their spraying on maize yield and components.

Kobayashi et al. 6 noted that iron absorbed by plants from mineral soils is not sufficient for its needs despite its availability, as iron moves from the roots after absorption to the target parts and appears yellowing of young leaves as iron moves to the buds through the xylem and then to the old leaves by the process of transpiration and pressure root. It also takes part in most biological activities, such as respiration, production of chlorophyll, and photosynthesis. It is a cofactor for enzymes involved in electron or oxygen transport because iron is required for biological activities but is harmful in excess. Singh et al. 7mentioned that using nano iron sprayed on the plant at various growth phases substantially influenced increasing vegetative growth and the yield and its components. Golshahi et al. 8 showed that iron is one of the determinants of plant survival, and its presence is reduced in highly acidic areas because of its active participation in physiological and metabolic processes necessary for plant growth.

Al-Shaheen et al. 9 indicated the effect of iron nanoparticles on maize yield. It increased the transfer of processed materials from the source (leaves) to the sink (grain) by increasing the rate of chlorophyll in leaves and accelerating the photosynthesis process, growth and productivity, thus increasing the yield. The goal was to investigate the influence of nanoiron concentrations and the timing of their spraying on maize yield and components.

MATERIALS AND METHODS

During the spring season of 2021, a field experiment was conducted in the experimental field of the College of Agricultural Engineering Sciences – University of Baghdad (Abi Ghraib site) to study the effect of nano iron concentrations and the dates of their application on maize yield and its components. The seeds of maize, cultivar Buhuth 106, were planted in furrows (75 cm apart) and 25 cm between plants, with a plant density of 53,333 plants ha-1. A factorial experiment was carried out in a split-plot arrangement. The spraying dates occupied main plots (beginning of the male flowering stage, 50% female flowering and completion of female flowering) and symbolized in sequence (D1, D2, and D3). In comparison, the iron concentrations (0, 100, 200 and 300 mg L-1) were allocated to the sub-plots based on the randomized complete design with three replications and symbolized in sequence (Fe0, Fe1, Fe2 and Fe3). The experimental unit was 3×2 m with 4 furrows, and the total number of treatments was 12 and 36 experimental units. A distance of 2m was left between one block and 1 m between one treatment and another. Nano iron was prepared by dissolving (1) gm in (1) liter of water. The quantities of 100, 200, and 300 ml were withdrawn, and the solution was completed to (1) liter to prepare the above concentrations, and distilled water was used as a control treatment. The spraying was done in the early morning until the plants were completely saturated.

Studied traits:

· The ear length was computed using the average length of the ears from the middle furrow of ten plants, which were taken randomly from the experimental unit.

· Number of rows in ear: It was determined by averaging the number of rows of grains for the 10 ears of plants chosen randomly in the experimental unit.

· Number of grains in a row: It was estimated using the average number of grains in a row for the 10 ears of plants chosen at random from the experimental unit.

· The number of grains ear-1: Calculated as an average of ten plants from the mid-furrow.

· Weight of 500 grain (gm): After years of harvesting, 500 grains from each experimental unit were combined and measured on a scale.

· Total grain yield (ton. ha-1): extracted from the yield of individual plants yield x number of plants/hectare and weight-adjusted based on moisture of 15.5% 10.

RESULTS

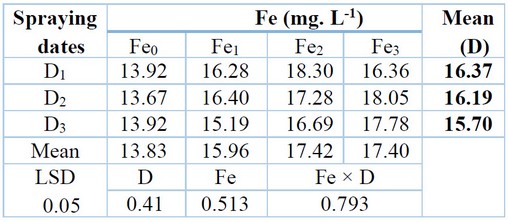

Ear length

The two spraying dates at the beginning of the male flowering stages (D1) and 50% of the female flowering (D2) were significantly superior, with the highest average ear lengths of 16.37 cm and 16.190 cm, respectively (Table 1). Meanwhile, for the lowest average length of the ear (15.70 cm) for the treatment (D3), there were no statistically significant changes between the two spraying treatments, D1 and D2. Early spraying may have given a greater opportunity to stimulate plant growth and increase the ear length. This result was confirmed by 11, who obtained a considerable increase in ear length after spraying the plant with nutrients at the start of ear development. The results showed that the increase in the concentrations of iron nanoparticles gave a gradual increase in the length of the ear after it was 13.53 cm when the control treatment reached the highest length of the ear at the concentrations 200 and 300 mg L-1 with an average of 17.42 and 17.40 cm, respectively.

The treatment (D1Fe2) showed that spraying nano iron with a concentration of 200 mg L-1 on the first date gave the highest ear length of 18.30 cm.

Table 1. Effect of foliar nano-iron and particle application on ear length.

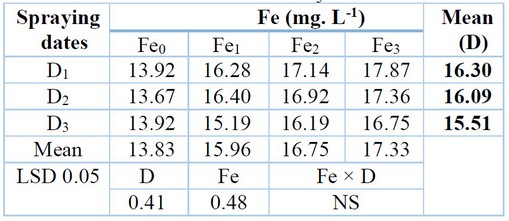

Number of rows in the ear

The first and second dates (D1 and D2) showed significant superiority in the number of rows for the ears (16.30 and 16.09 row ear-1, although the average number of rows was lowest on the third date (D3), at 15.51 rows, ear-1 (Table 2). Also, all iron concentrations outperformed the control treatment; the highest concentration of 300 mg L-1 gave it the highest number of rows of 17.33 ear-1. While there were no significant differences in the interaction of study factors.

Table 2. Effect of foliar nano-iron and particle application on number of rows per ear

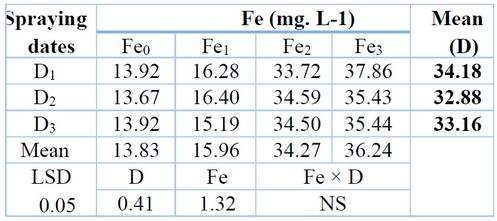

Number of grains. Row-1

There were no statistically significant differences between spraying dates and the interaction of study variables. While nano iron showed significant superiority in all its concentrations over the control treatment. The increase in iron concentrations was accompanied by an increase in the number of grains per row until it reached its highest average of 36.24 grain row-1 at the nano iron concentration of 300 mg L-1(Table 3).

Table 3. Effect of foliar nano-iron and particle application on number of grains. Row-1

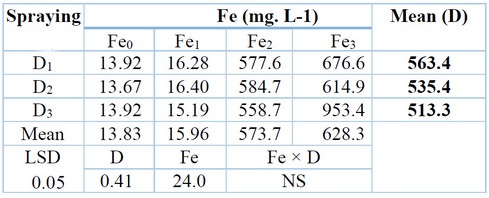

Number of grains. Ear-1

The first date of spraying produced the highest average amount of grains per ear (563.4 grain ear-1), which was reduced when spraying was delayed until it reached the lowest average amount of grains per ear on the third spraying date (Table 4). The concentration of nano-iron 300 mg L-1 gave the highest average number of grains (628.3 grains ear-1) and showed a significant difference between the other concentrations and the control treatment, which produced the lowest mean of 408.7 grains.

Table 4. Effect of foliar nano-iron and particle application on number of grains. ear-1.

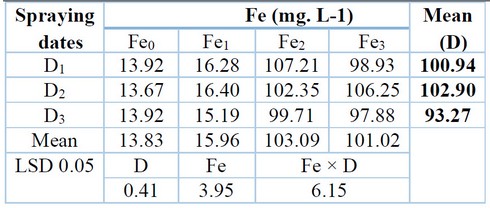

Weight of 500 grain(gm)

The two dates (D1 and D2) gave the highest weight for 500 grains, 100.94 and 102.90 gm, respectively, with a significant difference from the third date, with the lowest average for grain weight of 93.27 g (Table 5). According to the findings, increasing the concentrations of iron nanoparticles resulted in a significant increase in the weight of 500 grains, after it was 93.23 gm for the control treatment, reached the highest weight at concentrations 200 and 300 mg L-1 with an average of 103.09 and 101.02 gm, respectively. The findings show a significant interaction, and it seems that spraying 200 mg L-1in the first date (D1Fe2) produced the maximum value of grain weight (107.21 gm), which varied considerably from the treatment (D3Fe1), which produced the lowest rate of 84.00 gm.

Table 5. Effect of foliar nano-iron and particle application on number of grains. ear-1.

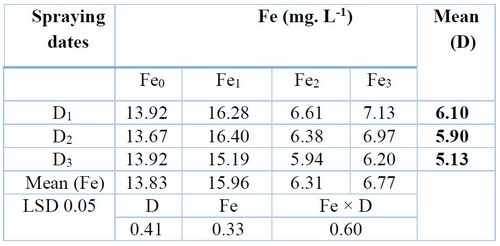

Total grain yield (ton. ha-1)

The first spraying date was significantly superior, with the highest average total grain yield of 6.096 tons. ha-1, compared to the other two dates, with the last date giving the lowest average grain yield of 5.130 tons. ha-1.

The findings indicate that increasing the concentrations of iron nanoparticles resulted in a significant increase in overall grain yield after 4.061 tons ha-1 for the control treatment reached the highest grain yield at the concentration of 300 mg L-1 with an average of 6.765 tons ha-1. According to the statistically significant interaction between the two parameters, spraying at a concentration of 300 mg L-1 on the first date resulted in the greatest value of grain production, which was 7.132 tons. ha-1.

Table 6. Effect of foliar nano-iron and particle application on total grain yield (ton. ha-1).

DISCUSSION

The addition of nano iron leads to an increase in the activity of photosynthesis processes by increasing the chlorophyll content in the leaves and increasing the ability of the crop to resist different stress conditions. As a result, there was an increase in the number of fertilized florets due to its indirect effect of increasing the size of the vegetative cover and the number of grains per row. This finding supports what Radwan et al. 12 concluded in their study of the response of some types of hybrid maize to mineral and nano fertilization, through which they concluded that adding mineral fertilizer in the soil by foliar spraying of nano fertilizer recorded the highest values for the number of rows in the soil. The ear and number of grains in each row were compared to the control treatment. This increase was reflected in the number of grains in the ear. This superiority is attributed to the effect of iron on stimulating dormant flowers and aiding in fertilization, which led to the distribution of nutritional quantities on all grains equally, which led to a prolongation of the period of accumulation of dry matter in the seeds and giving them the highest average number of grains 13.

The addition of nano iron led to an increase in the weight of 500 grains of maize, grain yield and dry weight of the plant, and this may be because the spraying is at the beginning of the male flowering stage and 50% of the female flowering, which is one of the critical stages in the life of the plant, and this raises the effectiveness The plant is in the process of photosynthesis, which increases the efficiency of the source (leaves) towards the sink (seeds). This result is consistent with previous research 14, which indicated that the foliar application in the flowering and fruit formation stage increased the weight of 500 corn kernels. This superiority can be attributed to the effect of nano iron, which has a high efficiency in targeting functional work centers by penetrating cell membranes and working on the synthesis of chlorophyll and promoting energy and its transfer, which helps in cell division, increasing the height of the plant and leaf area, increasing the amount of dry matter, and then increasing the weight of grains and yield—grain 9,15.

The addition of nano iron led to an increase in the weight of 500 grains of maize, grain yield and dry weight of the plant, and this may be because the spraying is at the beginning of the male flowering stage and 50% of the female flowering, which is one of the critical stages in the life of the plant, and this raises the effectiveness The plant is in the process of photosynthesis, which increases the efficiency of the source (leaves) towards the sink (seeds). This result is consistent with previous research 14, which indicated that the foliar application in the flowering and fruit formation stage increased the weight of 500 corn kernels. This superiority can be attributed to the effect of nano iron, which has a high efficiency in targeting functional work centers by penetrating cell membranes and working on the synthesis of chlorophyll and promoting energy and its transfer, which helps in cell division, increasing the height of the plant and leaf area, increasing the amount of dry matter, and then increasing the weight of grains and yield—grain 9,15.

CONCLUSIONS

It is concluded from this study that spraying iron element at the beginning of the flowering stage is the best, which was directly reflected in improving the characteristics of the components of the yield, which led to an increase in the grain yield, confirming that this stage is one of the sensitive and essential stages of the crop. The great response of the maize crop to spraying with iron is noted, especially at the higher concentration used in the study, which indicates the possibility of the crop responding to higher concentrations of iron.

Author Contributions: The following statements should be used: «Conceptualization, Naeem Mutlag. and Saddam Jiyad.; methodology, Saddam Jiyad.; software, Mohammed Youssef.; validation, Naeem Mutlag., Mohammed Youssef. and A Mustafa.; formal analysis, A Mustafa.; investigation, Naeem Mutlag.; resources, Saddam Jiyad.; data curation, A Mustafa.; writing—original draft preparation, A Mustafa.; writing—review and editing, Naeem Mutlag.; visualization, Saddam Jiyad.; supervision, Naeem Mutlag.; project administration, Naeem Mutlag, Mohammed Youssef, A Mustafa, and anSaddam Jiyad; All authors have read and agreed to the published version of the manuscript.

Funding: This research received no external funding.

Institutional Review Board Statement: Ethical review and approval were waived for this study because the research was not applicable.

Informed Consent Statement: “Not applicable

Data Availability Statement: You might exclude this statement if the study did not report any data.

Acknowledgments: Agricultural Fields Administration Officer at the College of Agriculture – University of Baghdad.

Conflicts of Interest: The authors declare no conflict of interest

REFERENCES

1. Ibrahim, H. I. Mahmoud.; Plant samples collected and analyzed. First edition. Dar Al-Fajr for publication and distribution. Egypt, 2010.

2. Gatea1, A. A,; M, H. Hamza and A. K. Hussein,; Effect of Spraying Several Concentrations of Yungrin Leaf Fertilizer on the Growth and Yield of Three Cultivars of Maize (Zea mays L.). Annals of RSCB, 2021; 25(4):11946 – 11955.

3. Martin, P.; Micro nutrient deficiency in Asia and the pacific Borax Europe limited. UK.AT. IFA. Regional Conference for Asia and the Pacific. Singapore. 2002; November.18-20.

4. Jin, Z.; Wang, M.; Wu L.; Wu, J.; Shi, C.; Impacts of combination of foliar iron and boron application on iron biofortification and nutritional quality of rice grain. J. Plant Nutria. 2008; 31(9): 1599-1611.

5. Meena, D. S. and B. N. Aravinda Kumar.; «Bio efficacy of nano zincsulphide (Zns) on growth and yield of sunflower (Helianthus annuusl.) and nutrient status in the soil. Bioinfo Publication. 2017; 9(6):3795-3798.

6. Kobayashi T, Nozoye T, Nishizawa NK. Iron transport and its regulation in plants. Free Radic Biol Med. 2019; Mar;133:11-20. doi: 10.1016/j.freeradbiomed. 10.439. Epub 2018; Oct 29. PMID: 30385345.

7. Singh, M.D.; G. Chirag, P. Prakash,; M.H. Mohan,; G. Prakasha and K. Vishwajith.; Nano-fertilizers is a new way to increase nutrients use efficiency in crop production. Inter. J. of Agric. Sci., 2017; 9(7): 38313833 –.

8. Golshani, S.; Gholamalizadeh, A.; Mir, N., and Ghorbani, M. The effect of foliar application of iron sources on growth parameters, iron concentration and activity of some enzymes of sorghum. J. of Water and Soil, 2017; 31(5). 10.22067/JSW.V31I5.64432.

9. Al-Shaheen, M. R.; Hamad, R. M.; Abdaly, M. M. A.; and Al-Rawi, O. H. Assessment the impact of iron nanoparticles and dry yeast extract on the corn (Zea maize L.). J. of Physics: Conference Series, 2020;1535(1):012052). IOP Publishing.

10. Hamad, H.M., Shabeeb, Z.A., Awad, M.M. Expressions of CD274 (PD-L1) and CD47 rReceptors on the sSurface of bBlast cCells in AML pPatients (2022) Iraqi Journal of Science, 63 (6), pp. 2373-2387.

11. Al-Janabi, Y. A.; N. M. Abood.; M, I. Hamdan. The Effect of Amino Acids and The Date of Planting on Yield and Some Yield Components of Three Maize Varieties. IOP Conference Series Earth and Environmental Sci., 2021; 904(1):012066. doi: 10.1088/1755-1315/904/1/012066.

12. Alkhateeb, A. R. .; Ibrahim, W. .; Taha, A. A. . Correlation Between Udder Conformation With Daily Milk Yield Of Buffaloes. JLSAR 2021, 2, 61–65.

13. S. Jalal, B., M. Ahmed, K. Field Survey And Molecular Detection Of Viruses Associated With Squash Mosaic Disease In Erbil Provence. Anbar Journal Of Agricultural Sciences, 2023; 21(1): 64-70. doi: 10.32649/ajas.2023.179716.

14. AL-Shumary, A. M.; Ali, H. A.; and AL Abdulla, S. A. effect of spraying concentrations of integrated nano-fertilizer on growth and yield of genotypes of corn (Zea maize L.). Muthanna J. of Agric. Sci., 2019; 7 (2): 114, 121.doi: 10.18081/MJAS/2019-7/114-121.

Received: 26 September 2023 / Accepted: 15 April 2023 / Published:15 December 2023

Citation: Mutlag, N. A.; Al-Rawi A.S.M.; El-Jubouri M.D.Y.; Cheyed, S. H. Response of maize grain yield and components to foliar iron nanoparticle application. Revista Bionatura 2023. Revis Bionatura 2023;8 (4) 70. http://dx.doi.org/10.21931/RB/2023.08.04.70