Vol 8 No 4 2023 – 50

Laboratory determination of spray characteristics using a full hollow cone nozzle at different heights and operating pressures

Athraa K. Hussain1, Majid H. Alheidary2,*

1 Department of Agricultural Machines and Equipment/ College of Agriculture/ University of Basrah/ Basrah / Iraq; dhrakhyry@gmail.com.

2 Department of Agricultural Machines and Equipment/ College of Agriculture/ University of Basrah / Basrah/ Iraq.

* Correspondence: majid.reshaq@uobasrah.edu.iq; Tel.: +9647733873816

Available from. http://dx.doi.org/10.21931/RB/2023.08.04.55

ABSTRACT

Reducing pesticide costs and environmental losses during spraying is considered an essential issue for obtaining the effectiveness of pest control. This study aimed to determine the spray characteristics using a full hollow cone nozzle at different spray conditions. Three spray heights, 25, 50, and 75cm, and three pressures, 2, 3, and 5 bar, were used. Nozzle flow rate, application rate, spray width, angle, and accumulated volume were measured. The results showed an effect on spray characteristics due to the change in spray conditions. The nozzle flow rate increased with the increase in pressure, where the average flow rate ranges between (0.34 to 0.58 l/min) between 2 and 5 bars, respectively. Results also illustrated an increase in height from 25 to 75 cm, and pressure from 2 to 5bar led to an increase in volume rate, spray width, angle, and accumulated volume (285.6 to 474.92), (50 to 100cm), (41 to 90º), and (37.75 to 198ml) respectively.

Keywords: Operating Conditions; Patternator; Nozzle; Spray Indicators.

INTRODUCTION

In the agricultural spraying processes, many processes should be done in fields, for example, controlling insects or weeds. Apart from these processes operations, spraying applications are also an essential issue to be carried out by the farmers to protect the cultivated plants from pests such as insects and fungi1. The concern of spraying applications for controlling any insect or disease is increasing quickly in several countries for qualitative income of agricultural products2. Spray volume is significant when control materials are added to the fields. Different parameters should be studied, such as nozzle type and size, working pressure, and nozzle height, to determine spray volume3,4. These parameters also influenced the uniformity of applied spray volume, coverage percentage, and nozzle angle5. The spraying processes under misapplication or without understanding appropriate conditions will lead to losses outside the intended target3, 6. In spraying application, both accuracy and uniformity of spray volume on the zone target are essential to avoid the opposite influences of chemical products on crop injury and the environment and reduce pest management7. Nozzle flow rate, operating pressure, spray nozzle angle, spray nozzle height, spray nozzle width, etc., are the factors that influence the agricultural nozzle performance 8 9 10. Agricultural nozzles come in various types, each with unique properties and functions for various spraying tasks. To achieve the desired spray characteristics, a nozzle must be chosen based on the operating pressure and spray height, which impacts the concern of yields11. In Iraqi farms, there needs to be more details about the full hollow cone nozzle, considered the famous nozzle in the fields. So, this study was designed to determine the spray characteristics at different operating conditions using a horizontal patternation in the laboratory, which could be associated with adopting the convenient spray nozzle for plant protection.

MATERIALS AND METHODS

The sampling mechanism of the spraying machine was utilized in the Department of Agricultural Machines and Equipment, College of Agriculture, University of Basrah. The investigations were performed at the laboratory to determine spray characteristics using different operating conditions. Different laboratory investigations are carried out to evaluate the nozzle flow rate, spray application volume, spray width, spray angle, and accumulated spray volume. The mechanism of spraying was adjusted at various nozzle heights (25, 50, and 75 cm) and different working pressures (2, 3, and 5 bar).The nozzle flow rate was measured using collecting tubes for an exposure time (10 seconds) for all experiments.

This study selected the full hollow nozzle type to investigate the spray distribution pattern under different operating conditions; these nozzles are considered popular in Iraqi farms.

Measuring the uniformity of spray volume distribution

The spray volume uniformity throughout the boom nozzle or within the spray width is essential for obtaining maximum efficacy with minimum cost and low spray volume to non-target intended contamination. The uniformity of the spray nozzle was determined using a patternator. The patternator typically consists of several channels (46 grooves) aligned perpendicular to the spray nozzle and can be of any appropriate length, provided that it encompasses the spray area. A nozzle spray volume distribution pattern, which was 240 cm x 150 cm in size, was observed on the patternator. The patternator has 46 grooves at equal spacing (5 cm) and a rack to carry spray-collecting tubes, which were mounted separately under the collecting endpoints of each groove. The nozzle boom was positioned vertically above the patternator at 25, 50, and 75 cm heights. The spraying mechanism was operated for 10s in each condition and could achieve a measurable spray volume rate from the accumulation tubes. This process was replicated three times for each flowrate, and then the average was determined individually based on the employed operating pressure and nozzle height11.

Measuring of spray application volume

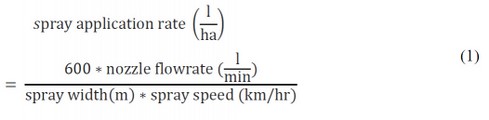

The actual spray application rate of the spray mechanism was calculated by measuring the nozzle flow rate and spray swath width (m). The spray width is equal to one spray nozzle. The spray application rate was calculated using the following formula:

Measuring spray nozzle width

The width of the spray nozzle was calculated by measuring the distance between the spray’s outer edges when the nozzle operated at the nozzle height and the operating pressure was fixed. For each nozzle height, the external grooves of the patternator that received 50% or more of the maximum amount of water collected from any groove while the operating pressure increased must be measured.

Measuring the spray angle

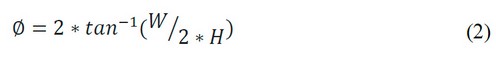

The distance located between the right and left of the spray nozzle at constant operating pressure and spray height is used to calculate the spray angle. The first stage for calculating the spray nozzle angle is to measure the spray volume accumulated by tubes. According to the following formula, the spray angle was determined:

Where ɵ: is the spray angle (º); W: is the spray width (cm, total number of full tubes with water* the distance between two adjacent grooves of the patternator); H: is the spray height (cm).

Statistical analysis

Data of spray volume were statistically analyzed using ANOVA tables12.

RESULTS

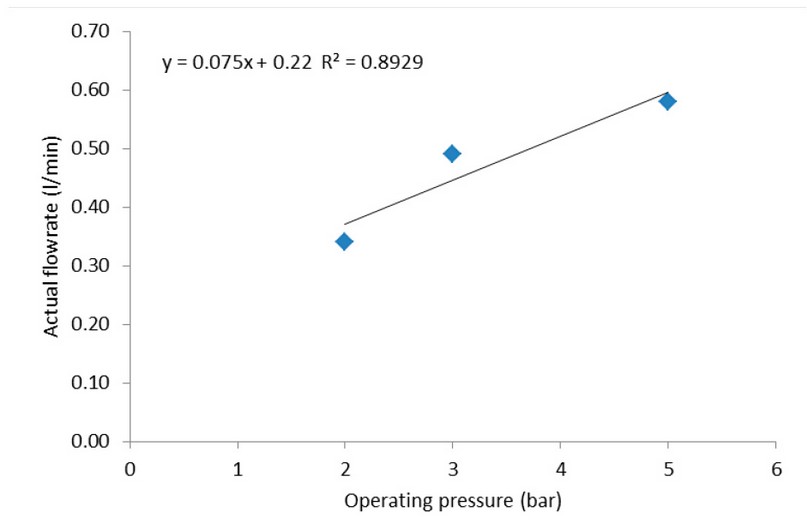

Effect of the operating pressure on the nozzle flow rate

As shown in Figure 1, the actual nozzle flow rate values are according to operating pressure. The actual nozzle flow rate was significantly affected at different operating pressures. The results of the nozzle flow rate showed that as the working pressure increased from 2 bar to 5 bar, the nozzle flow rate increased from 0.34 to 0.58 l/min. This result agreed with 9, which mentioned significant differences in a nozzle flow rate as a result of an increase in the operating pressure.

Figure 1. Nozzle flow rate values according to operating pressures.

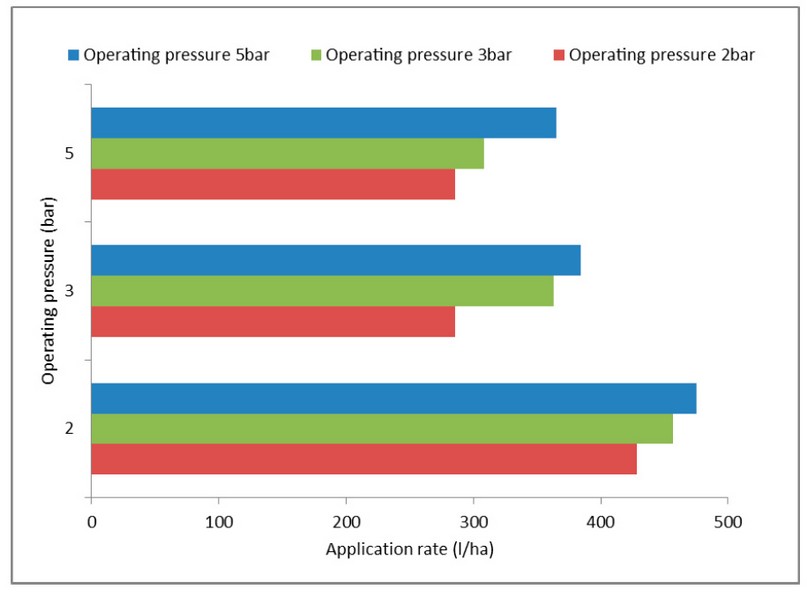

Effect of operating pressure on spray application rate

Figure 2 shows that the spray application volume around the patternator is recovered by increasing the nozzle flow rate due to increased operating pressure. The amount in spray application rate (285.6 l/ha) was lowest for the operating pressure of 2 bar compared to other operating pressures. Meanwhile, the highest operating pressure (5 bar) results in a high spray application rate (474.94 l/ha). This result agreed with 9due to the increase in nozzle flow rate while increasing operating pressure, thereby increasing the spray application rate.

Figure 2. Application rate amount related to operating pressures.

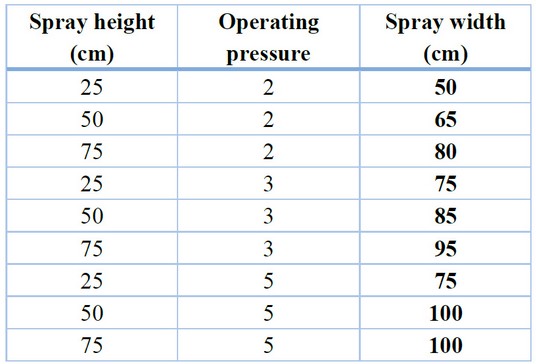

Effect of spray height and operating pressure on spray width

Table 1 illustrates the recorded values for the spray width at different nozzle heights and operating pressures. The results of spray width were significantly affected by both spray height and working pressure. The outcomes of spray width showed that the spray width of the nozzle increased due to increasing the spraying nozzle height operating pressure, or both. It was also observed that the spray width varied from 50 to 100 cm, and the maximum spray width was recorded for a nozzle height of 75cm at an operating pressure of 5 bar. In addition, results in Table (1) showed that the spray width for the full hollow cone was increased from 50 to 80, from 75 to 95, and from 75 to 100cm by increasing the nozzle height from 25 to 75 cm at 2, 3, and 5 bar respectively. Also, the maximum spray width for the full hollow cone nozzle was 100 cm at 75 cm height and an operating pressure of 5 bar, while the minimum spray width was 50 cm at 25 cm nozzle height and pressure of 2 bar. This result agreed with 11, showing that the spraying height and operating pressure were directly related to spray width.

Table 1. Spray width is related to spray height and operating pressure.

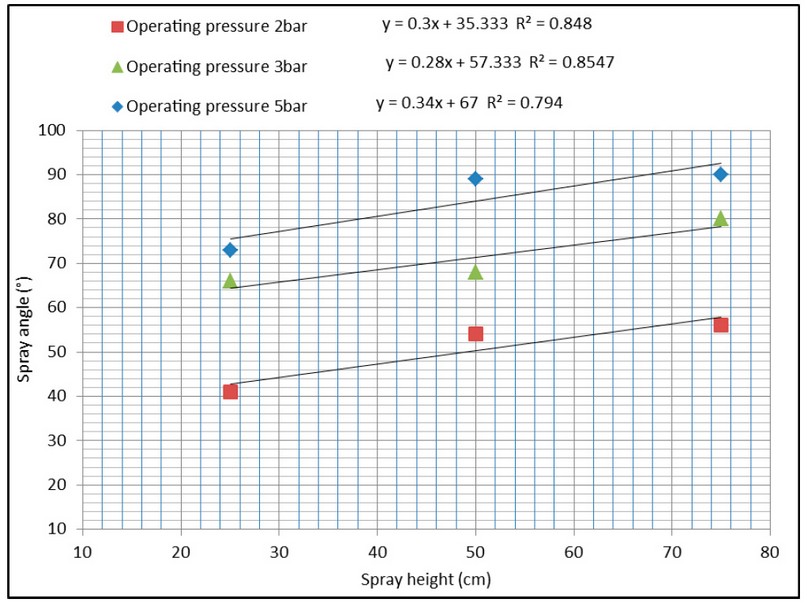

Effect of spray height and operating pressure on the spray angle

The results of spray angles in Figure 3 indicated that spray height and operating pressure significantly affect the spray angles due to the differences in the spray width distribution.

Increasing spray height and operating pressure led to an increase in spray angle. Compared to other spray heights and operating pressures, a higher spray angle (90º) was measured at an operating pressure of 5 bar and a spray height of 75 cm. The smallest spray angle (41º) was measured at the spray height of 25 cm and operating pressure of 2bar compared to other treatments. This result agreed with 11 due to increased spray width, height, and operating pressure.

Figure 3. How do spray height and operating pressures affect spray angle.

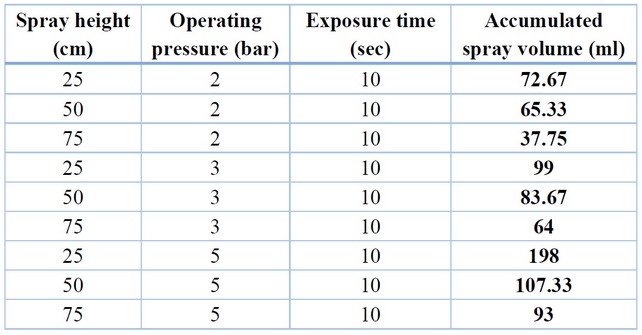

Table 2. Amounts of spray volume at different operating conditions.

Effect of operating pressure and spray height on accumulated spray volume

Results in Table 2 revealed that a spray angle of more than 50° reduces the spray peak value under the orifice nozzle center. The results also appeared to increase the nozzle angle from 50 to 90° due to an increase in the spray height or operating pressure or an increase in spray width and the total amount of spray accumulated along the patternator. Using high operating pressure (5 bar) instead of the low operating pressure (2 bar) led to improved spray distribution on the grooves of the alternator and an increase in spray width and angle and an increase in accumulated spray volume. This outcome agreed with 13, which mentioned the distribution of cumulative volumetric spray droplets influenced by nozzle characteristics and operating pressure.

DISCUSSION

This study is beneficial because it focuses on the effects of operating conditions such as operating pressure and spray height using a full hollow cone nozzle, considering that these factors are the most critical influences on spray droplet distribution at the time of spraying processes using any agricultural sprayers to improve the control efficacy and decrease pesticide costs and losses. The main findings of this study showed significant differences in the characteristics of the spray, such as spray width, spray angle, application rate, and accumulated volume deposits on the patternator using different nozzle heights and operating pressures. The spray characteristics were robustly correlated to the spray height and pressure. These results agreed with the previous studies 4, 5, 9, 10. The highest spray height and operating pressure mean the greatest spray width, angle, and accumulated spray volume according to 9, 11, 13.

CONCLUSIONS

The determination of spray characteristics using a full hollow cone nozzle was investigated under different spray heights and operating pressures. The findings showed that spray characteristics such as nozzle flow rate, application rate, spray width, angle, and accumulated volume were closely related to spray height and operating pressure. The insufficient or excessive values of spray characteristics in the spraying application revealed that these values varied with the spray height or operating pressure or together.

Author Contributions: The conceptualization, Alheidary, M.; methodology, Alheidary, M.; software, Alheidary, M.; validation, Alheidary, M. and Hussain, A.; formal analysis, Alheidary, M.; investigation, Hussain, A.; resources, Hussain, A.; data curation, Alheidary, M.; writing—original draft preparation, Hussain, A. and Alheidary, M.; writing—review and editing, Alheidary, M.; visualization, Alheidary, M.; supervision, Alheidary, M.; project administration, Alheidary, M.; funding acquisition, Hussain, A.. All authors have read and agreed to the published version of the manuscript.

Funding: Self-funding.

Acknowledgments: No organization or agency has provided financial assistance for this work.

Conflicts of Interest: The authors declare no conflict of interest.

REFERENCES

1. Tudi M, Daniel Ruan H, Wang L, Lyu J, Sadler R, Connell D, et al. Agriculture Development, Pesticide Application and Its Impact on the Environment. IJERPH. 2021;18:1112.

2. Singh K, Padhee D, Parmar AK, Sinha BL. Development of a solar-powered knapsack sprayer. J. Pharmacogn. Phytochem. 2018;7:1269–72.

3. Sumner PE. Soybean Sprayer Application and Calibration. The University of Georgia; 2009. Report No.: 8.

4. Ghanim, I. .; Ebrahim, S. E. . Preparing Of Bio-Cement Mortar By Using Bacillus Licheniformis Bacterial Cells. JLSAR 2022, 3, 23-29.

5. Foqué D, Nuyttens D. Effects of nozzle type and spray angle on spray deposition in ivy pot plants. Pest Manag Sci. 2011;67:199–208.

6. F. T. Al-Rawi, Y. T. Abdul-Rahaman , Abdullah I.Noaman , Th. T. Mohammed, S. M Abdulateef, Nadia Jebril and KI. Mahmud. Role of ascorbic acid and appetite stimulants on a few blood serum biochemical characteristics in pregnant Iraqi ewes under heat stress. Al-Rawi F T, Abdul-Rahaman Y T, Noaman Revis Bionatura 2022;7(4) 6. http://dx.doi.org/10.21931/RB/2022.07.04.6.

7. Alheidary MH, Hamed DS, Jaber FN. Optimal efficacy of the essential nozzle characteristics and insecticide type for controlling cabbage aphids. JCP. 2021;10:511–22.

8. Agriculture College, Alheidary MHR. Performance of knapsack sprayer: effect of technological parameters on nanoparticles spray distribution. IJETT. 2017;46:199–207.

9. Abdul-Lateif, K. M. & Abdulateef, S. M. The effect of injecting hatching eggs with different concentrations of biotin on the quality and physiological characteristics of the hatched chicks. Iraqi J. Vet. Sci.2012, 26.

10. Alheidary MHR. Influence of nozzle type, working pressure, and their interaction on droplets quality using knapsack sprayer. IQ J Agr Scs [Internet]. 2019 [cited 2022 Aug 1];50. Available from: http://jcoagri.uobaghdad.edu.iq/index.php/intro/article/view/702

11. Sh. H. Fayyad, L., A. Sh. Al Shaheen, M. Effect Of Root Treatment With Mycorrhiza And Foliar Application With Moringa Leaf Extract On Npk Elements In Citrullus Colocynthis Leaves. Anbar Journal Of Agricultural Sciences, 2023; 21(1): 124-132. doi: 10.32649/ajas.2023.179722.

12. Ali, H.H., AL-Rawi, K., Khalaf, Y., Alaaraji, S., Aldahham, B., Awad, M., Al-ani, O., Al-ani, F., Ali, A.T.Serum Caveolin-1 Level is Inversely Associated with Serum Vaspin, Visfatin, and HbA1c in Newly Diagnosed Men with Type-2 Diabetes.Reports of Biochemistry and Molecular Biology,2022, 11 (2), pp. 299-309.

13. Cerruto E, Manetto G, Papa R, Longo D. Modelling Spray Pressure Effects on Droplet Size Distribution from Agricultural Nozzles. Appl. Sci. 2021;11:9283.

Received: 26 September 2023 / Accepted: 15 April 2023 / Published:15 December 2023

Citation: Hussain, A. K. ; Alheidary, M. H. Laboratory determination of spray characteristics using a full hollow cone nozzle at different heights and operating pressures. Revis Bionatura 2023;8 (4) 55. http://dx.doi.org/10.21931/RB/2023.08.04.55